|

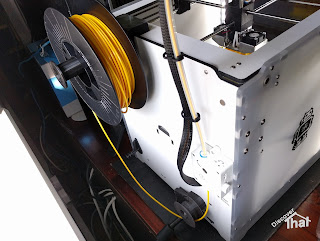

| Upside down, for printing |

This is a spindle for the spool with bearings in. There are loads of designs available that do the same thing. Most involve clamping the spool in some way to a spindle containing bearings.

I like to be able to easily lift the spool on and off. I see no advantage in a complex clamp. Before creating this my spools just loosely hooked on a fixed shaft. A bit looser than the original clip in spindle which is very fiddly to work with. This design is just an evolution of the hook but with bearings to make the spindle run freely.

This has worked very well the spool spins freely.

Bill of materials:

1x M8x110mm bolt

1x M8 nylon locknut

2x M8 Form A (normal) washers

1x M8x25mm or penny washer

3x 8mm axle 22mm x7mm bearings (from skates)

Optional:

2x 10mm O/D x1mm thick lengths of aluminium tube cut to fit as spacers between the bearings

The 3D printed parts:

1x Hook support (no supports needed)

1x Spacer (no supports needed)

2x Spindle halves (with supports from the bed)

==

Downloads:

Filament Spindle STL files (zip)

==

No comments :

Post a Comment