Defender 1984 to 2016

Hazard and Indicator Lights Diagnostics

“Many problems with the indicators are actually faults with

the hazard switch.”

Wiring Differences

The various models of Land Rover Defenders from 1984 through

to 2016 have similar wiring but have slightly different colour wires

connected at the hazard switch.

The wiring colours are written as the main colour first with the stripe colour after. As an example, a light green wire with a white stripe would be written as Light Green/White (LGW). A grey (slate) wire with a brown stripe would be written as Slate/Brown (SN).

After 1998, the colour of the ignition feed changes to White/Green and the permanent feed to Purple/Brown.

Operation

To better understand the significant functions, only the indicator operation is described in the following. The panel

lighting and tell-tale light functions are not noted here:

|

When off (not

depressed) Indicators

can be used. |

+12V to the

flasher relay is supplied from the ignition feed. The ignition

has to be in position two for the indicators to work from the column

controls. == +12V ignition,

Dark Green or White/Green, depending on the model year, is connected to the Light

Green wire to the flasher unit. |

|

When on

(depressed) Hazard

lights in use. |

+12V

permanent feed is connected to the flasher unit. The return

from the flasher is connected to both the left-hand and right-hand side

indicators. Both sides

indicators will flash. == Permanent

+12V Purple or Purple/Brown wire is connected to the Light Green wire to the

flasher unit. The Light Green/Brown return wire from the flasher unit is connected to both the Green/Red and Green/White feeds to the indicator lamps. |

Diagnostics

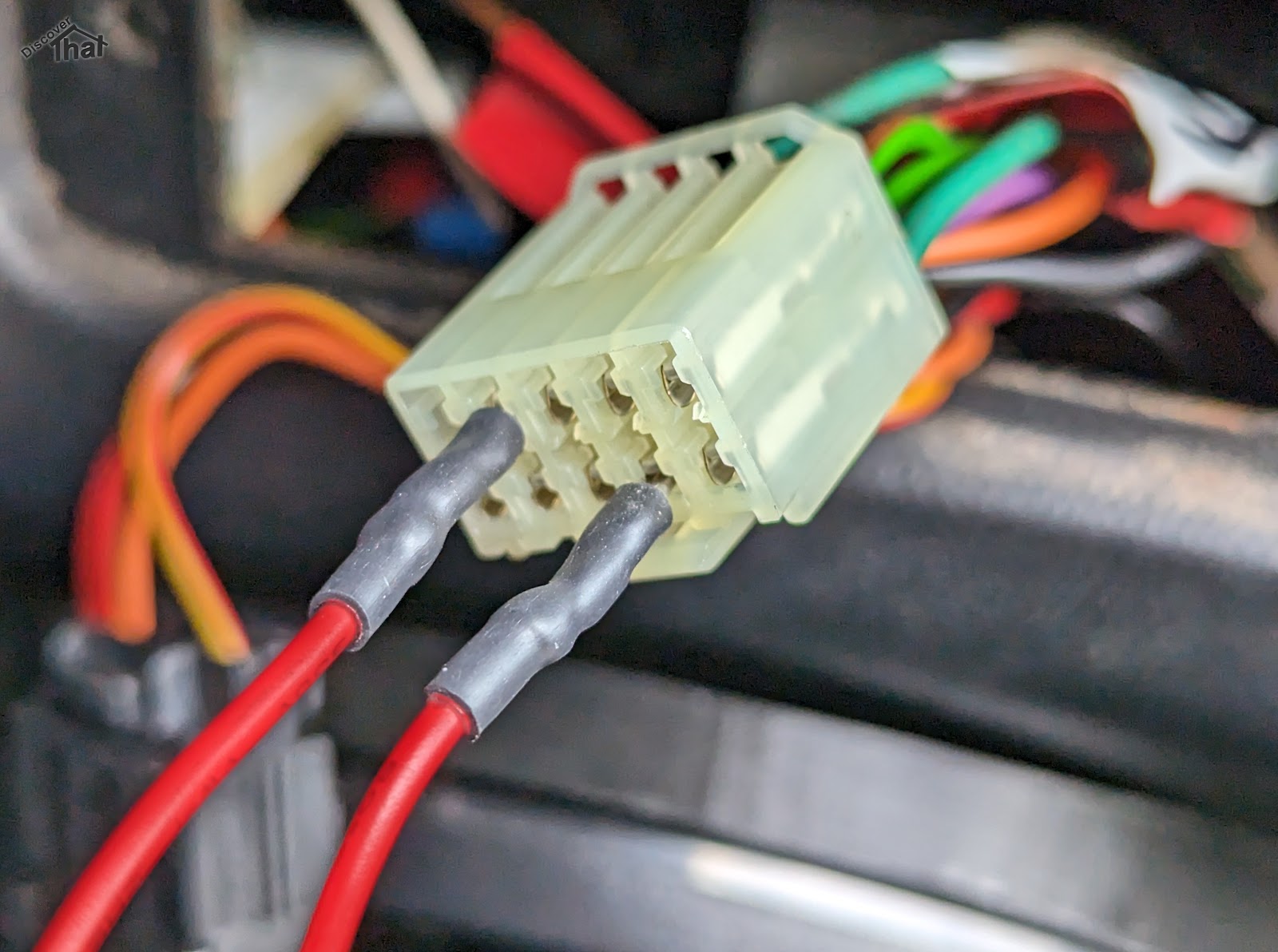

I like to make up a test wire using an inline fuse. This is to avoid

mistakes accidentally shorting out a live to earth. A 5A fuse is suggested. It

needs to be less than 10Amp to avoid the fuse box fuse blowing first.

Most indicator faults can be diagnosed via the hazard switch

connector.

|

To Test |

Method |

Expected

Result |

|

Indicator wiring |

At the hazard

switch connector. Connect the

permanent live, Purple or Purple/Brown, to the Left and Right indicator

wires, in turn. Left is

Green/Red Right is

Green/White |

The

indicators on one side would illuminate. Not flashing. |

|

Flasher unit and

indicator controls |

At the hazard

switch connector. Connect the

permanent live, Purple or Purple/Brown, to the Light Green flasher feed. Operate the

indicator stalk switches. |

The appropriate

indicators should flash. |

|

Ignition

live feed |

At the hazard

switch connector. Repeat the

above two operations using the ignition feed Green or White/Green wire, in place of the Purple wire. The ignition switch must be in position two. |

Same results

as above. |

|

Indicator

stalk switches |

At the

indicator stalk pins. Bridge the Light

Green/Brown common wire from the flasher to the indicator wires, in turn: Left is

Green/Red Right is

Green/White |

The

appropriate indicators should flash. |

Just in-case anyone notices. The photos are from a 1998 300TDi re-wired to use the switches from a newer 2002 onwards TDCi.

Troubleshooting

|

Bridging any of the wires at the connector works but using the switch fails. |

Clean the

connector pins on both the connector and out the back of the switch. If the above

fails to resolve the issue, it will be necessary to replace the switch. |

|

Either

bridging of the permanent or ignition wire tests fail. |

Check the

appropriate fuse. |

|

The indicator

lamps illuminate when connected to a live but do not work through the flasher

unit. |

Remove the

flasher unit from its socket and clean the pins. If the above

fails to resolve the issue, it will be necessary to replace the flasher unit. |

Cleaning Connector Pins

This can be done with a pencil rubber or more commonly with

fine sandpaper. A needle file can be useful to get into confined spaces.

Where the electrical interface is inaccessible, a chemical

contact cleaner can be used, however this often also needs the connector to be

inserted and removed a few times to assist the cleaning process.

If the connector pins do not hold tightly, small, pointed

nose pliers can sometimes be used to gently close up the female portion of the

connector pins.

Fuses

Ignoring the main fuses and links because there would be

other symptoms if they had blown.

|

Up to 1998 300TDi |

Permanent

Feed, Purple – Central interior fuse box Fuse 1 (15A) Ignition

lighting feed, Green – Central interior fuse box Fuse 3 (15A) |

|

1999 to 2001 Early TD5 |

Permanent

Feed, Purple/Brown – Central interior fuse box Fuse 31 (15A) Ignition

lighting feed, White/Green – Central interior fuse box Fuse 21 (10A) |

|

2002 to 2016 Late TD5 |

Permanent

Feed, Purple/Brown – Central interior fuse box Fuse 31 (15A) Ignition

lighting feed, White/Green – Central interior fuse box Fuse 21 (10A) |

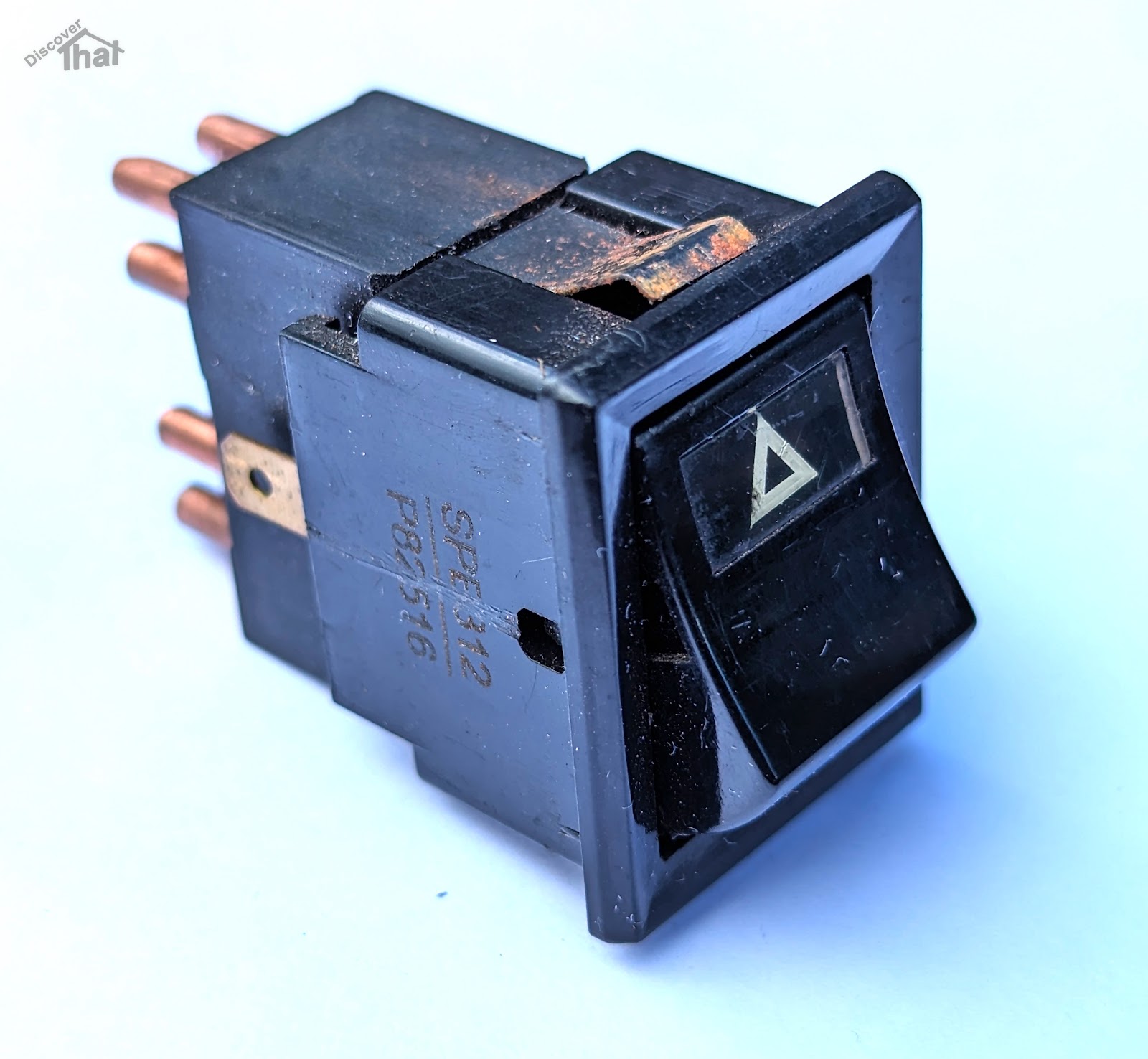

Switch Types

|

Defender 1983 to 2001 TD, 200TDi, 300TDi and early TD5 YUF101490

Lucas switch |

|

|

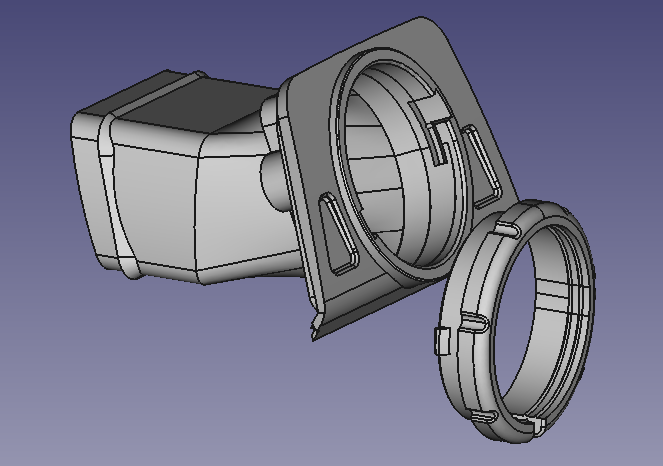

Defender 2002 to 2016 Late TD5 and TDCi Puma YUG000180LNF |

|

|

Freelander 1996 to 2002 YUG102220 |

The early Freelander hazard switch body is the same as the late Defender. It uses the same wiring and connector but the key cap is different. In the event that a Defender hazard switch is not available, that era Freelander switch can be used as an alternative. In order to make it fit the dash panel, the key cap needs to be carefully removed and swapped over with the Defender key cap. It is held on by two plastic clips, one top and one bottom.

|

I'll add to this if I discover any more tips.

I only have direct experience of a 1998 300TDi and a 2009 TDCi. All other information is taken from manuals and third-hand information. There are likely to be exceptions and some cars, like my own, will have been modified.

==